Aluminium for high achievements: roller skis for Olympians and schoolchildren

Sectors

Sectors

31.05.2022 - The Aluminium Association

KTM-2000, an architecture anodising company from Belarus, part of the Aluminium Association, focuses on unique and complex aluminium anodising technology for architecture, design and industry. But there is also a completely unusual product in its range: the SkiBel aluminium roller skis, created under public and private partnership with the utility company Minsktrans, which maintains the transport system of Minsk. This sports equipment, which is popular in many European cities, is designed for training of beginners and professional skiers and biathletes on asphalt.

Own ski track

Roller skis appeared in the 1930s as an auxiliary sport equipment for skiers who did not want to interrupt training during the off-season. Skis with rollers first spread to Northern Europe and Italy. The very first roller skis were made in Sweden, Germany and Austria, where a wooden or metal frame 70 to 100 cm long was installed on pneumatic wheels with an impressive diameter of 35 cm: one wheel in the front and two others in the rear (at a distance from each other). Only 40 years after their invention, roller skis turned from auxiliary item into an independent equipment: in the 1970s, roller skis competitions began to be held.

Protected by oxide

The project of KTM-2000 and Minsktrans have an interesting background. 'I myself have devoted 12 years to skiing, including alpine skiing, and I know from my own experience how hard it is to train when several people use the same skis. So, when I was offered to participate in this project, I gladly agreed, joined in and involved our best specialists in this project,' says Taras Gvozdkov, CEO of KTM-2000, architecture anodising company.

All models of produced SkiBel roller skis (skibel.by) are made of aluminium extruded from a special hard alloy EN AW 6005A in compliance with EN 573-3, using high strength quenching (T66 condition). Development of the roller skis design, selection of strengthening technology, selection and testing of materials: all this was implemented on the basis of Minsktrans Mechanical Repair Plant.

'We tested the standard 6060/6063 alloy, but the roller skis started to bend when being used by the athletes, especially from the national team. Then our colleagues from Alutech (editor's note: the Aluminium Association's member) offered us a reinforced 6005 alloy with additional heat treatment. To improve the characteristics, we increased the extrusion wall thickness. Alongside with that, we are looking for someone to order even harder extruded alloys: 6061 or 6082. The 7075 (B95) alloy seems to be a perfect option, but we only make rods from it, while in China they know how to make extrusions of this material,' said Taras Gvozdkov.

The production of roller skis is a multi-stage process. At the first stage, aluminium extrusions are cut depending on the model parameters. For example, the shortest roller skis, Elite, are only 550 mm long, and the largest roller skis, Skate 100 Long, with an longer frame, have a platform length of 710 mm. Then the already cut extrusions are transferred to mechanical milling area, where wheel holes are cut.

To improve the performance (wear resistance, corrosion resistance, light resistance) and attractiveness of roller skis, KTM-2000 were the first roller skis to use the technology of protective and decorative anode oxidation with galvanic printing. Aluminium is converted into oxide, making the product surface hard, smooth and matte. This is performed using an automatic anodising line, where the part is sequentially moved through a set of different baths. Then the process is interrupted for galvanic printing and after the pattern is applied on all sides of the roller ski, the part is hot compacted at about +100 °C. Thanks to this treatment, aluminium is transformed on the surface of the roller skis into a very hard oxide with a porous structure, into which the image was applied, similar to tattooing, when ink is injected under the skin.

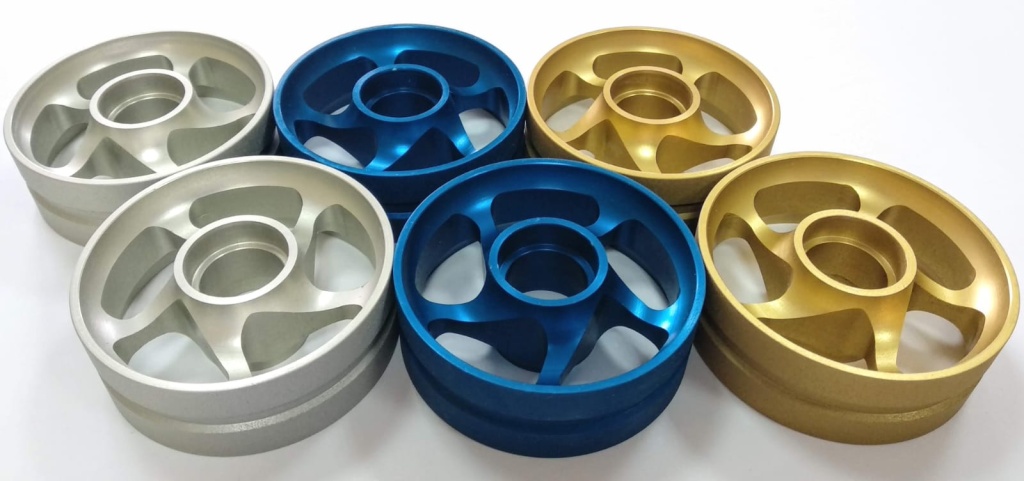

At the same time, wheel hubs (discs) and as mud flaps of various colours are made in the casting area. For more expensive roller skis models, special aluminium hubs are made from duralumin: these are almost like cast or forged car wheels. Then, depending on the purpose of the wheel application, these hubs are either rubberised or polyurethane wheels are cast for them. This is followed by installing the wheel hub on the roller ski frame. All roller skis are supplied complete with covers, which are sewn at Minsktrans by order: with the symbols of various skier or biathlete teams.

Together for a common futureSkiBel roller skis are suitable for both schoolchildren and Olympians. Lightweight (minimum 1.25 kg per item) and strong roller skis have optimal torsional rigidity for bending and flexing. For two years, the company has made more than 5,000 roller skis for children's sports schools and national skiing and biathlon teams of Belarus.

Products with individual characteristics were made for prominent athletes. Owners of truly unique roller skis included the three-time Olympic champion, the head of the Russian Cross-Country Skiing Federation, Elena Vyalbe and Olympic champions Alexander Legkov and Alexander Bolshunov.

Taking into account all the above, we can firmly say that the project, which resulted in the SkiBel roller skis, fully corresponds to the slogan of the 2022 Olympics in Beijing: 'Together for a Common Future'.

REFERENCE

Founded in May 2000, the architectural anodising company KTM-2000 has its own production area (4,000 sq. metres). The experience gained over more than 20 years and the constant desire of development pushed KTM-2000 to create its own innovations: selective chemical engraving ArtELOX and HybridELOX, a combination of selective chemical engraving and galvanic printing.

The quality of products is confirmed by the Qualanod international certificate, which is actually the standard in the field of anodising for architecture and industry. This is the only system in the world to confirm high standards, quality of anode coatings and a guarantee of colour repeatability. The smelter is especially proud of the Sandalor license designed for architectural applications. Sandalor is a quality mark in the field of non-ferrous anodising for architecture. Of all the anodising processes, Sandalor is considered the most complex one. The architectural anodising company KTM-2000 is the only Sandalor licensee in Eastern Europe. Today, there are only eight valid Sandalor licenses in the world.